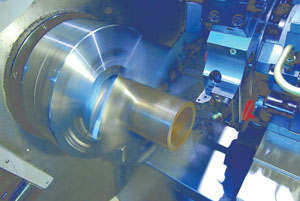

Precision machining services with cutting edge technology

Superior Machine is a technology based company focused on meeting the highest standards and tightest tolerances in our machining processes. Our precision equipment is capable of producing machined parts to a tolerance of .0002. Superior Machine is capable of precision machining to extreme tolerances on even the most difficult materials to work with.

Our machining equipment

- Vertical CNC Milling

- (2) Haas VF3SS VMC 12,000 RPM – 40″ x 20″ with full 4th axis milling

- (2) Haas VF2SS VMC 12,000 RPM – 30″ x 15″ with full 4th axis milling

- YCM NSV-102A VMC 10,000 RPM, 40″ x 20″ with 5th axis milling

- (2) YCM XV-1020A VMC 10,000 RPM – 40″ x 20″

- (3) YCM FV56A VMC 10,000 RPM – 20″ x 16″

- YCM NSV-156A VMC 10,000 RPM – 60″ x 25″

- Ares Seiki A560 15,000 RPM, 22″ x 16″ XY Travels

- Doosan DVC 320/40 Rotary pallet changer 12″ x 20″

- Haas 3 axis tool room mill

- (2) Accurite 2Axis CNC Mill

- CNC Turning/Mill Turn

- Daewoo Puma 2100SY Live tooling w/sub spindle and Y axis milling

- Daewoo Lynx300M Live tool Lathe

- Daewoo Lynx 200L CNC Turning Center

- Daewoo Lynx 200C Turning Center

- Manual Equipment

- Nardini Engine Lathe

- Do-All Automatic Surface Grinder

- Complete Inspection Department

- Micro-vu Sol vision system

- Brown Sharpe Global Classic 575 Programmale CMM

- TESA Micro-Hite 3D CMM

- Optical Comparator

- LCD Microscope

- Gibbs CAM Programming software

- JobBOSS Estimating and scheduling software

- PC DMIS CMM Inspection software

If you would prefer a PDF file of the equipment list, you can download the Superior Machine Line Card.

Selection of High Quality Materials

Superior Machine Inc. works with a wide range of materials, including stainless steel, aluminum, mild and tool steels, and many types of plastics. We will work with you to determine the appropriate material for your job.

Job Management with State of the Art Software

To expedite quotes and manage all CNC machining projects from order entry through shipment, we use a high tech program that allows all involved parties to view quotes, orders, progress, shipping, and billing information.

Outstanding Quality Control

Our quality control department operates under strict internal procedures that include pre and post-finishing inspections. Upon request, we can implement additional inspections as needed including inspection reports. We use the latest programmable CMM inspection equipment in conjunction with GD&T (Geometric Dimensioning and Tolerance Inspection) to monitor and maintain tolerances within .0002.

Complete Finishing Services

Superior Machine handles all finishing processes for your precision machined components to achieve the highest quality, appearance and durability.